Design and Stress Analysis of Screw Shaft for Peanut Oil

The oil and cake are usually collected at the oil outlet and press cake exit. Screw shaft is the main component of the oil extraction machine. Existing screw press oil expeller is the JY 200 machine with 220W motor power and 1500rpm. The von-Mises stress of existing screw design is 94.11 MPa and the modified screw design is 89.876 MPa for theoretical.

The grinder in the oil expeller is in the form of screw on the shaft. This screw shaft is rotated in the parallel direction and crushing the oil seeds. The arrangement of the screw and its shaft is made in the way that the material is progressively compressed as it moves on, discharge at end of the cylinder.

ICMIEE-PI-160363 Design and Construction of Oil Expeller

Design and Construction of Oil Expeller Press with Structural Analysis of Screw with Ansys Md. Habib Ullah Khan, Dipayan Mondal, Shahidul Hoque shaft. Worm shaft is the heart of screw press as

A mechanical oil expeller press was designed, constructed & further analyzed with simulation software (ANSYS) in this research work. This expeller can be useful for small scale oil extraction. ASME shaft design code was used in designing the screw shaft of the press.

Oil Extracting Screw Press Designs

French oil extracting screw presses have several features which make our screw presses superior to others, including: French is the only company with a screw press designed to water-cool its main cages in addition to cooling the main shaft. When full pressing, this benefit reduces the temperature rise,...

of diameter 30 mm was used for the worm shaft. 2.3.2. Design of the screw thread The worm shaft is essentially a tapered screw conveyor with the volumetric displacement being decreased from the feed end of the barrel to the discharge end. The screw treading system was design as a step up shaft diameter and decreasing screw depth using the expression in the

the machine to extract crude oil

processed. A straight screw shaft configuration is commonly used screw press and easy to produce. These following type of screw shaft configuration are used in processing seed oil industry over 50 years [3]. For first configuration of screw press, the pitch and the root diameter are constant through the screw press as shown in Figure 2.

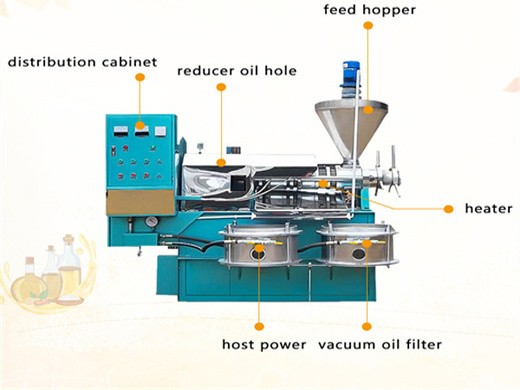

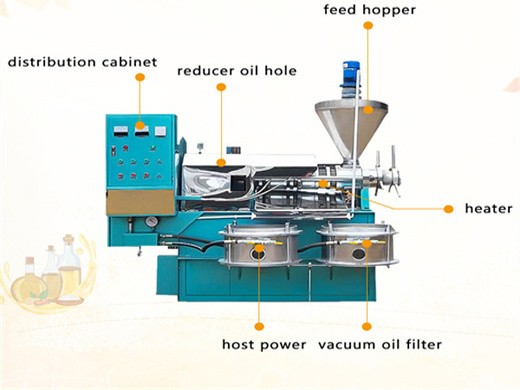

Do you want to set up a cooking oil factory to making edible oil by yourself ? All you need to do is buy our best-sale mini cooking oil press machine, cooking oil pressing machine , cooking oil

ICMIEE-PI-160363 Design and Construction of Oil Expeller

Design and Construction of Oil Expeller Press with Structural Analysis of Screw with Ansys Md. Habib Ullah Khan, Dipayan Mondal, Shahidul Hoque shaft. Worm shaft is the heart of screw press as

expulsion and conclusions drawn from these experiments led to the design of twin screw oil expeller. By considering various factors such as throughput, power requirements and material selection, the detailed design of machine is started. It includes twin screw shaft designs, Barrel designs, Slotted Barrel

Design of Machine Elements : Force analysis of Worm gears

PTC Creo (Pro E) Design & Creat worm gear animation (Number of starts =1) (ウォームギアを作ってみた) - Duration: 10:54. ngo duong 19,002 views

GET PRICE

Screw press and its performance - SlideShare

Screw press and its performance 1. Screw press and its performance Pragati Singham M.Tech (FPEM) 2. CONTENTS • • • • • • Introduction Types Construction & working Principle Performance(design) References 3. INTRODUCTION • It is the simplest machine for separation of solids and liquids.

GET PRICE

Copra Oil Expeller for Sale, Coconut Oil Press Machine

1. Copra oil press consists of feeding mechanism, worm shaft, bar cage, cake thickness adjusting mechanism, adjusting cooker and driving mechanism. The worm shaft of the coconut oil making machine has seven sections of worms and six sections of intermediate collars sleeved on the shaft.

GET PRICE

Press Design | Vincent Corp - Dewatering Screw Press

Press Design; Screw Press Videos; Contact. Newsletter Signup; Press Design. Batch Mode Screw Press Operation CIP for Screw Presses Compressive Mechanisms in a Screw Press Conical Screw Shaft Cord Cutter Explosion Proof Motors Cooking Oil Recovery; Fiber Filter; Food Waste; General and Miscellaneous; International Agents;

GET PRICE

Oil Expeller - Oil Screw Press and Oil Seed Screw Press

Forerunner in the industry of oil extraction, our range of Oil Expeller / Oil Screw Press is superior in technology and functioning. There is a great demand of our oil expellers in the industry. With excellent capability of extracting best quality oil and cake from all known oil seeds, these are developed in wide range of capacities.

GET PRICE

Expanding and Expelling - American Oil Chemists' Society

The Expeller – Screw Press - Design The worm shaft in the press today consists of individual worm elements, conical rings or toothed mixing rings. The free volume of the worm elements and their conveying capability decrease from inlet to outlet. The cold-pressed pre-press oil may be treated by a separate filtration system.

GET PRICE

Press Design | Vincent Corp - Dewatering Screw Press

Click on the following links to learn more about our press designs

GET PRICE

How does sunflower oil press machine work?_Tech sunflower

When working,put the processed sunflower seeds into the sunflower oil press machine from the hopper under running condition.The sunflower seeds continues to be pushed inward as the worm shaft rotates,while the sunflower oil flows out of the oil outlet.

GET PRICE

High Capacity Oil Press Machine - Goyum Screw Press

High Capacity Oil Press Machine. Features of High Capacity Screw Press. This model has been designed in a simple and symmetrical shape. Triple Reduction Gear Box with helical gears of cast steel and pinion shafts of special steel. Gearbox is aligned with all the bodies on a single fabricated base. Main Worm Shaft can be withdrawn

GET PRICE

Find Natural Cold Oil Press,Double Screw Expeller Oil

FEATURES 1. All such main parts of this Oil Press machine as worm shaft ,pressing worms,cage and so forth are made of high-grade alloy 2. Steel through hardening treatment. As a result,in spite of the conditions of high temperature and abrasion under which they

GET PRICE

Oil Press - Cold Press Oil Machine Manufacturer from Ludhiana

Manufacturer of Oil Press - Cold Press Oil Machine, Industrial Oil Press, Oil Press Machines and Oil Press Machine Manufacturers offered by Shreeji Expeller Industries, Ludhiana, Punjab. Shaft Withdrawal The main Worm Shaft can be withdrawn very easily without disturbing the gear section in any way and pressure worms and spacing collars can

GET PRICE

Worm Gear Mesh Geometry | SDPSI

Cylindrical worms may be considered cylindrical type gears with screw threads. Generally, the mesh has a 90° shaft angle. The number of threads in the worm is equivalent to the number of teeth in a gear of a screw type gear mesh. Thus, a one-thread worm is equivalent to a one-tooth gear; and two-threads equivalent to two-teeth, etc. Referring

GET PRICE

Oil Expeller - Screw Oil Press Manufacturer, Supplier

Oil Expeller – an Important Component of Oil Extraction Plant. Oil expeller, also known as screw oil press machine and it’s the heartbeat and most important oilseeds extraction machine in the whole vegetable oil extraction plant. Goyum Oil Expeller is suitable for small scale, medium and large scale oil extraction plant.

GET PRICE

OIL PRESS RANGE

The oil will be squeezed out with a single pressing (full pressing method). An adjustable gear drive system allows a fast change between different kind of seeds and trouble free adjustment of the press is made by changing the worm shaft rotation.

GET PRICE

Oil Press - Cold Press Oil Machine Manufacturer from Ludhiana

Manufacturer of Oil Press - Cold Press Oil Machine, Industrial Oil Press, Oil Press Machines and Oil Press Machine Manufacturers offered by Shreeji Expeller Industries, Ludhiana, Punjab. Shaft Withdrawal The main Worm Shaft can be withdrawn very easily without disturbing the gear section in any way and pressure worms and spacing collars can

GET PRICE

Expanding and Expelling - American Oil Chemists' Society

The Expeller – Screw Press - Design The worm shaft in the press today consists of individual worm elements, conical rings or toothed mixing rings. The free volume of the worm elements and their conveying capability decrease from inlet to outlet. The cold-pressed pre-press oil may be treated by a separate filtration system.

GET PRICE

Effect of Expeller Press Parameters on Fish Oil Extraction

Increase in screw (worm) shaft speeds from 50 to 70 rpm was observed to decrease extraction loss. The results obtained from the study of the effects of expeller press parameters on fish oil extraction showed that choke clearance, screw clearance and screw speed influenced oil extraction significantly at 95 % confidence level.

GET PRICE

How does sunflower oil press machine work?_Tech sunflower

When working,put the processed sunflower seeds into the sunflower oil press machine from the hopper under running condition.The sunflower seeds continues to be pushed inward as the worm shaft rotates,while the sunflower oil flows out of the oil outlet.

GET PRICE

Press Design | Vincent Corp - Dewatering Screw Press

Click on the following links to learn more about our press designs

GET PRICE

Development of a small capacity double stage compression

Fig. 2 shows the material flow through a small section of the worm channel (Vadke, Sosulski & Shook, 1988).As the mixture of the oil and solids passes through several such sections, it is subjected to a radial pressure. This pressure is generated due to volumetric compression along the screw barrel, and is exerted by the shaft.

GET PRICE

Expeller- Oil Expeller, Oil Expellers Machines

Capacity 50-60 TPD in single press and 125-150 TPD in pre-press. 'UMAS' VIP MK-5 Oil Expeller, all steel fabricated, with triple reduction helical gear box with self lubrication arrangement, vertical hinged cast steel chamber, self contained conveyor for oil, alloy steel water cooled main worm shaft, fitted with hard faced worm assembly.

GET PRICE

NEW SCREW PRESS - Serptec

NEW SCREW PRESS SPECIALLY DEVELOPED FOR RENDERING. FOOTPRINT Easily positioned on existing press footprints SHAFT & CAGE. 360° screening area. Improved oil yield. Easy maintenance. Hydraulic cage opening Worm Assembly. High quality components. Increased wear life. Multivaliant design. Eliminates the choke

GET PRICE

Effect of Expeller Press Parameters on Fish Oil Extraction

Increase in screw (worm) shaft speeds from 50 to 70 rpm was observed to decrease extraction loss. The results obtained from the study of the effects of expeller press parameters on fish oil extraction showed that choke clearance, screw clearance and screw speed influenced oil extraction significantly at 95 % confidence level.

GET PRICE

All About Expeller Presses | The Olive Oil Source

The compression effect can be achieved, for example, by decreasing the clearance between the screw shaft and the cage ( progressive or step-wise increase of the shaft diameter ) or by reducing the length of the screw flight in the direction of the axial movement The gradually increasing pressure releases the oil which flows out of the press

GET PRICE

Development of a small capacity double stage compression

Fig. 2 shows the material flow through a small section of the worm channel (Vadke, Sosulski & Shook, 1988).As the mixture of the oil and solids passes through several such sections, it is subjected to a radial pressure. This pressure is generated due to volumetric compression along the screw barrel, and is exerted by the shaft.

GET PRICE