Soybean Oil Production Line, Soybean Oil Extraction Plant

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.

Soybean seed processing flow chart shows how the seed is processed to make oil from Seed of the Soybean. Leading manufacturer of Oil Screw Press.

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

Soybean Oil Solvent Extracting Process The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil.

Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then further purified. Solvent Extraction Workshop View:

Improving the yield of soybean oil extraction process

Improving the yield of soybean oil extraction process by using of microwave system M. Ghazvehi , M. Nasiri* School of Chemical, Gas and Petroleum Engineering, Semnan University,Semnan, Iran

Soybean Oil Extraction Process The extraction of soybean oil from soybean flakes in soybean oil plant industry requires large amounts of hexane solvent and results in significant losses and energy consumption during the distillative removal of the solvent.

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

Soybean Oil Solvent Extracting Process The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil.

Project Name : Complete Fish Oil Extraction Plant (Solvent Extraction) Factory Location : Pakistan Production Output : 50 ton/day Fish Oil Extra... 1 ton/h Mini Feed Mill Plant If you are planning to start mini feed mill plant for herbivore and ruminate animals, you can take this feed milling project for reference.

Soybean oil extraction process ppt__Industry News

Soybean oil solvent extraction process. 3.Cooking oil refining machine is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil. Craft flow of soybean oil refining machine : Soybean oil refining process. More information about soybean oil extraction process ppt,you can contact us! We will give you suprised.

For manufacturers of large quantities of soybean oil production and processing, it is also very tempting. Besides, good soybean oil press equipment also has longer service life than poor ones. In addition, due to the high oil rate of soybean, it could easily lead to clogged oil line in the pressing process. So you can add small amount of cake ...

High quality soybean oil processing machine, soybean oil

Pretreatment is to adjust the soybean into best state before pressing or solvent extraction, in order to increase oil output rate and improve oil and cake or meal quality. The standard soybean pretreatment technology mainly includes cleaning, crushing, softening, flaking and cooking.

GET PRICE

Enzyme-Assisted Aqueous Processing of Soybeans (Year 2

Soybean commodity boards, such as the United Soybean Board, the American Soybean Association, and the Iowa Soybean Promotion Board. PROJECT MODIFICATIONS: We did not scale-up the enzyme-assisted aqueous extraction process to large-scale pilot-plant trials as planned because significant advances were still being made to the process as carried out in the laboratory and we judged it to be premature for such trials.

GET PRICE

Whole soybean protein extraction processes: A review

Within industry, aqueous extract from whole soybeans is commonly used for making consumer products containing both soy protein and soybean oil, and this has been the focus of this review. Key extraction process parameters are presented and challenges of each extraction step are given for the whole soybean extraction process.

GET PRICE

Mechanical Soy Processing: An Environmentally Friendly Method

Early mechanical methods, used presses to “squeeze” the oil from the soybean, however oil extraction rates were 50% at best, and often times generated excessive heat causing damage to the vital nutrients.

GET PRICE

Soybean Oil Production Method and Knowledge

The soybean oil production (pressing) process. Secondly, take every detail into consideration for the pretreatment of soybean. In the process of air drying for soybean, the straw, mud, sand etc. must be removed thoroughly. Thirdly, in soybean steam frying process, pay attention to the control of the furnace.

GET PRICE

Soybean Oil Extraction and Biodiesel

BSBios History. • Intecnial and Crown Iron Works built the BSBios Biodiesel Project • Operations started in 2005 with BSBios buying soybean oil and producing Biodiesel • Started only with biodiesel process / pretreatment and single controller • There were 3 operation workstations, without engineering and maintenance workstations.

GET PRICE

Soybean Oil Production Line-Soyoil Solvent Extracting Plant

Soybean Oil Solvent Extracting Process The pretreated soybean flakes are sent to the soybean solvent extraction plant. The plant uses a kind of solvent (normal hexane) to absorb the oil from soybean, and then the machines separate the solvent from soybean crude oil.

GET PRICE

Soybean Oil Mill / Oil Extraction Plant Manufacturers

Soybean Oil Pressing. TThe soybean contains 16 – 18 % oil content. In the First mechanical pressing, over 12 – 13 % of the total oil will be extracted. Remaining oil, leaving 5 – 5.30% oil in the oil cake which will be used in food and animal feeds, principally as a protein supplement. Oil Filtration. The crude soybean oil contains foots that needs to be removed.

GET PRICE

Analysis of the Hexane Loss in a Vegetable Oil Extraction Unit

Analysis of the Hexane Loss in a Vegetable Oil Extraction Unit Teresa Varandas Roque1, Maria Joana Neiva Correia1, ... anomalies and make proposals for improvement in order to reduce the hexane’s losses and the ... The calculated the ratio for Iberol’s process for soybean turned out to be low. Increasing this ratio to 0.9,

GET PRICE

Project Profile

The Soya bean oil is extracted from the seed by Solvent Extraction Method. It is a process of diffusion of solvent in to the oil bearing cells of the raw material resulting a solution of the oil in the solvent “Hexane”. The entire process is largely divide in to three main sections as follows: a. Preparatory Section : An efficient extraction would need that every oil bearing cell of the material is

GET PRICE

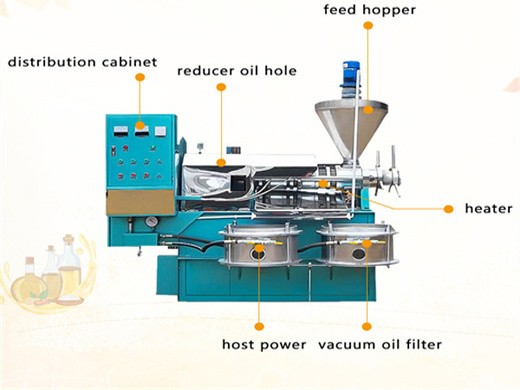

Soybean Oil Extraction Machine Press Oil Efficiently

Soybean oil extraction process maybe have a little different based on the region, raw materials, capacity, and the requirements for final products. Therefore, we generally offer custom-made plan and extraction process based on the specific requirements. Complete Soybean Oil Extraction Process . In conclusion, if you are looking for an ideal ...

GET PRICE

Soybean Oil Extraction and Biodiesel

• Historical data was manually collected with missing process engineering data inserted later to further analysis. Later… • BSBios decided to produce degummed own soy oil from soybean seeds. • Intecnial built the entire project -"Project Turnkey“ • In 2010, started the new complex BSBios -storage and crushing of soy

GET PRICE

Three phase partitioning for extraction of oil from soybean

Three phase partitioning, a method generally used for protein separation, has been evaluated for extraction of oil from soybean. 82% oil was extracted within 1 h using this process which required simultaneous addition of t-butanol (1:1, v/v) and 30% ammonium sulphate to the soybean slurry.

GET PRICE

Soybeans Oil Processing Machine/Jatropha Seeds Oil Press

Castor Oil Processing and Castor Oil Press. Castor Oil Press. In the entire process of castor oil processing, castor oil press can also be used for peanuts, beans, sesame, soybean, cotton seed, flax, sunflower seed, coconut, cacao, jatropha seed, tea seed, prickly ash seed, chilli seed, corn germ, and other many kinds of oilseeds plants.

GET PRICE

Manufacturer, supplier of Soybean oil processing machine

The whole set soybean oil processing machine is composed of soybean oil pretreatment and pre-pressing machine, soybean oil solvent extraction plant and soybean oil refinery plant. Henan Doing Company is the best soybean oil processing machine manufacturer and supplier in China, with a wealth of experience in designing and manufacturing various ...

GET PRICE

"Sustainability analysis of soybean refinery: soybean oil

Soybeans are one of the main sources of oil crops around the world. Soybean oil is the most common product of soybean refinery. It is a resource of edible oil and has other food and industrial applications. Techno-economic analysis (TEA) is applied to estimate the economic feasibility of the soybean oil extraction process. The mechanical extruding-expelling process, hexane extraction, and ...

GET PRICE

Solvent Extraction - SRS BiodieselSRS Biodiesel

Solvent Extraction is a process which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods (such as expellers, hydraulic presses, etc.) The solvent extraction method recovers almost all … Continue reading →

GET PRICE

What is the process of soybean oil extraction machine?

Commercial soybean oil extraction is a complex process. The traditional method for soybean oil extraction was a mechanical process using hydraulic presses. Because it was expensive and produced lower yields, the mechanical production process has given way to production by means of extraction with solvents.

GET PRICE