Technologies for extraction of oil from oil-bearing

Request PDF | On Jan 1, 2005, A. Ibrahim and others published Technologies for extraction of oil from oil-bearing agricultural products: A review | Find, read and cite all the research you need on

Keyword: oil extraction, oil bearing agricultural products, Vegetable oil extraction. Abstract: This paper is designed for people who have little or no technical background or earlier knowledge of oil extraction processing.It provides a vital introduction to both traditional and improved methods for the extraction of vegetable oil from oilseeds.

Novel oil extraction technologies: Process conditions

3 OIL EXTRACTION TECHNOLOGIES 3.1 Aqueous enzymatic extraction Aqueous extraction is a traditional technique that uses water as a solvent to extract oil from oleaginous materials. Because water takes long to degrade the cell wall of oil-bearing mate-rial, the process is less effective and results in low yield. To

Oil extraction is the process of recovering oil from oil-bearing agricultural products through manual, mechanical, or chemical extraction. The agricultural products are classified into oil-seeds (cotton, castor, sunflower, etc), nuts (coconut, groundnut, sheanut, etc) and mesocarps or fruits (oil palm).

Ultrasonic technologies for extracting oil products

Ultrasonic technologies for extracting oil products from oil-bearing sands and contaminated soils. Abstract. The kinetics of the extraction of oil products (bitumen, oil, and fuel oil) from natural and model oil-bearing sands after ultrasonic treatment was studied.

The oil extraction is the most important step in biodiesel production and it varies depending on the part that contains oil, either the kernel or the seed. They are ground using an industrial grade blender (Fig. 7.1).Apart from all these steps, the preequisite for oil extraction is the seed preparation [28].

Ultrasonic technologies for extracting oil products

Ultrasonic technologies for extracting oil products from oil-bearing sands and contaminated soils

Other traditional systems used in rural oil extraction include the use of heavy stones, wedges, levers and twisted ropes. For pressing, a plate or piston is manually forced into a perforated cylinder containing the milled or pulped oil mass by means of a worm. The oil is collected below the perforated chamber.

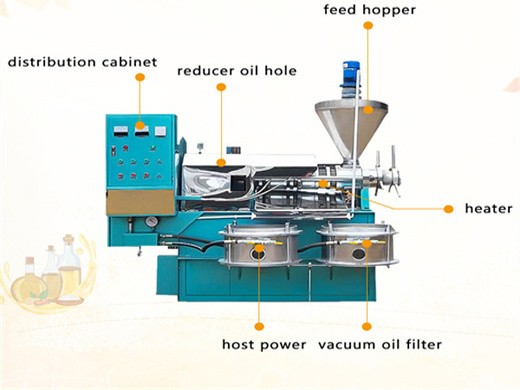

DESIGN AND DEVELOPMENT OF GROUNDNUT OIL EXTRACTING MACHINE

Abstract - A critical appraisal of technologies for oil extraction from oil-bearing agricultural products is presented. Different types of oil- bearing agricultural products are discussed. The products include; groundnut, coconut, sheanut , castor, sunflower, sesame, oil-palm, etc . In India, most of land

Nevertheless, vegetable oil extraction consumes large quantities of hexane, and therefore, there is a need to explore green technologies such as aqueous enzymatic‐assisted extraction and green solvents such as ionic liquids and terpenes (Sahad, Md Som, & Sulaiman, 2014).Green solvents present a huge potential to replace the commonly used n‐hexane without compromising the quality of oil and

A SIMPLE METHOD FOR DETERMINING THE OIL CONTENT OF SEEDS

to all types of oil-bearing materials. MODIFICATION OF THE TECHNIC OF THE WESSON TEST The Wesson method was studied in all its details in the grain research laboratory of the Bureau of Agricultural Economics and, 1 WESSON, D. NEW OPTICAL METHOD FOR DETERMINING OIL IN OIL-MILL MATERIALS. Cotton Oil 4 (3) : 70-73. 1920.

GET PRICE

Novel oil extraction technologies: Process conditions

Novel oil extraction technologies: Process conditions, quality parameters, and optimization College of Agricultural Engineering and Technology, CCS Haryana Agricultural University, Hisar, Haryana, 125 004 India. and their industrial applications. Besides, the review highlights the optimized parameters for oil extraction from different

GET PRICE

Extraction of Vegetable Oils from Agricultural

Extraction is an important unit operation in crop/food processing; involving the recovery of a material of interest from a parent material. Vegetable oil extraction has presented a lot of

GET PRICE

Chapter 5 : Processing and refining edible oils

Oil can be directly extracted with solvent from products which are low in oil content, that is, soybean, ricebran and corn germ. After sterilization, oil-bearing fruits are pulped (digested) before mechanical pressing often in a screw press. Palm kernels are removed from pressed cakes and further processed for oil.

GET PRICE

Life cycle assessment of novel technologies for algae

Overall, the acoustic harvesting & extraction technology only requires a small amount of electricity to complete the biomass harvesting to oil extraction process, without external chemicals or materials needed, and therefore offer significant GHG emissions reductions compared to GREET base case process technologies based on gate-to-gate analysis.

GET PRICE

New Oil Drilling Technology Will Soon Spark An Explosion

New Oil Drilling Technology Will Soon Spark An Explosion Of Oil. I wrote about new drilling techniques and other technology that promised to bring oil and gas production costs significantly lower.

GET PRICE

Eco-innovative technologies for extraction of proteins

Significant oil-bearing crops are olive, palm and coconut, from which oil is extracted from fruit pulp, whose residues can be used for protein extraction (Roselló-Soto et al., 2015). Apart from coconut oil meal, coconut residue remaining after coconut milk extraction can be used for isolation of proteins (Rodsamran & Sothornvit, 2024).

GET PRICE

Green solvents and technologies for oil extraction

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents.

GET PRICE

Life cycle assessment of novel technologies for algae

Overall, the acoustic harvesting & extraction technology only requires a small amount of electricity to complete the biomass harvesting to oil extraction process, without external chemicals or materials needed, and therefore offer significant GHG emissions reductions compared to GREET base case process technologies based on gate-to-gate analysis.

GET PRICE

Solvent Extraction Method for Edible Oil Processing

Solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and Hexane is the preferred choice. Industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing. Hexane-based processes have been in commercial

GET PRICE

Green Technologies for the Oil Palm Industry | Dominic C.Y

The book reports an overview of green technologies in palm oil milling processes, such as new alternative solvents and extraction processes developed for the extraction of biochemicals from various palm oil wastes which are then re-engineered into new products in other innovative applications

GET PRICE

Processing and Farming Equipment in the Hemp Industry

Hemp farming requires substantial agricultural knowledge and research, as the exact equipment used will depend on the precise growing methodology. Another critical factor in which equipment a farmer chooses is whether or not the hemp will be used for textiles or for CBD oil.

GET PRICE

New Oil Drilling Technology Will Soon Spark An Explosion

New Oil Drilling Technology Will Soon Spark An Explosion Of Oil. I wrote about new drilling techniques and other technology that promised to bring oil and gas production costs significantly lower.

GET PRICE

Non-Edible Plant Oils as New Sources for Biodiesel Production

Moreover, they reported that 75 oil bearing plants contain 30% or more oil in their seed, fruit or nut. Subramanian et al. reported that there are over 300 different species of trees which produce oil bearing seeds. Thus, there is a significant potential for non-edible oil source from different plants for biodiesel production as an alternative

GET PRICE

Mechanical Extraction Processing Technology for Biodiesel

Mechanical Extraction Processing Technology for Biodiesel Introduction Oil separation, the extraction of oil from seeds or plant parts, is accomplished by mechanical pressing, sometimes followed by chemical extraction.

GET PRICE

Green solvents and technologies for oil extraction

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents.

GET PRICE

Pressing Extraction - an overview | ScienceDirect Topics

Extraction of oil from oil-bearing seeds consists mainly of four major steps: • Pre-treatment of the raw material: During this step the oil-bearing seeds are cleaned, dried, and de-hulled. Then clean seeds are weighted and passed to a de-stoner and a magnet to remove stones and metals, then prepared for oil extraction and cooking. •

GET PRICE

Novel Technologies for Food Processing and Shelf Life

Novel Technologies for Food Processing and Shelf Life Extension Prof. Hari Niwas Mishra Department of Agricultural and Food Engineering Indian Institute of Technology, Kharagpur Lecture – 31 Extraction of Oil (Part 2 – Solvent Extraction) In the second part of the lecture on Extraction of Oil from oil seeds, solvent extraction method will

GET PRICE

Oil & Gas - GGB Bearing Technology

In the unforgiving conditions of the oil and gas industry, stress, heat and contamination constantly threaten to derail the performance of drilling equipment, pumps and other oil and gas extraction equipment. In these environments, where safety is paramount and downtime is costly, GGB’s heavy duty bearings for the oil and gas industry provide the performance and durability to keep operations

GET PRICE

Solvent Extraction of Castor Beans Oil: Experimental

Optimization of percentage of oil yield extracted from castor seed was carried out using response surface methodology and Box-Behnken design. Castor oil was extracted using solvent extraction with three different solvents; hexane, petroleum-ether and ethanol.

GET PRICE

Solvent Extraction Method for Edible Oil Processing

Solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and Hexane is the preferred choice. Industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing. Hexane-based processes have been in commercial

GET PRICE

CPE: Lesson 7. Processing of oil seeds

Coconut is dehusked and split manually by skilled operators. Most oilseeds (copra, palm kernels and groundnuts) need grinding in mills before oil extraction to increase the yields of oil. All oil-bearing materials need to have correct moisture content to maximize the oil yields. 7.2 Oil Extraction methods. a) Mechanical expression

GET PRICE

Emerging Green Technologies for Processing Oil-seeds

Emerging Green Technologies for Processing Oil-seeds Author: Vipin Chandra Kalia Introduction The major crops as the source of edible oil are mustard, groundnut, castorseed, safflower, linseed, nigerseed, soybean and sesamum. The demand for edible oils is increasing globally. Interestingly, the difference between demand and supply is around 75%.

GET PRICE

Novel Technologies for Food Processing and Shelf Life

Novel Technologies for Food Processing and Shelf Life Extension Prof. Hari Niwas Mishra Department of Agricultural and Food Engineering Indian Institute of Technology, Kharagpur Lecture – 31 Extraction of Oil (Part 2 – Solvent Extraction) In the second part of the lecture on Extraction of Oil from oil seeds, solvent extraction method will be studied.

GET PRICE

Can technology save the palm oil industry? | News | Eco

At the last stage of the production chain, Sime Darby has been developing technology in the oil mill to improve the oil extraction rate. The current technology extracts 20-21 per cent on average, and the new machines are looking at increasing the extraction rate by about 1 per cent, though it is still being tested.

GET PRICE