Separation of soybean oil/n-hexane and soybean oil/n

After membrane conditioning, separation assays using industrial miscella and synthetic miscellas of refined soybean oil/n-hexane were carried out for oil/n-hexane mass ratios of 1:3 and 1:1 (w/w) and the transmembrane pressures (TMP) of 3, 4 and 5 bar.

It can be seen that heating evaporation is not only the solvent in the mixed oil, but also must be combined with the stripping method. The conventional separation of mixed oil can be divided into two steps: ①The mixed oil evaporates, which is heated by indirect steam and evaporated by solvent.

Separation of n-butane from soybean oil mixtures using

Separation of refined soybean oil/n-butane mixtures was studied in this work using different commercial ultra- and nanofiltration membranes, with cut-offs ranging from 1 to 5 kDa. Refined soybean oil/n-butane mixtures at 1:3 (w/w) and 1:1 (w/w) mass ratios were continuously fed to a tangential flow module.

Separation of refined soybean oil/n-hexane miscellas was studied using different commercial ultra-and nanofiltration membranes, with cutoffs in the range of 1 to 5 kDa and salt rejection higher ...

Separation of Soybean Oil From Liquefied n-butane

Separation of Soybean Oil From Liquefied n-butane and Liquefied Petroleum Gas by Membrane Separation Process Article in The Canadian Journal of Chemical Engineering 93(1) · October 2014 with 63 Reads

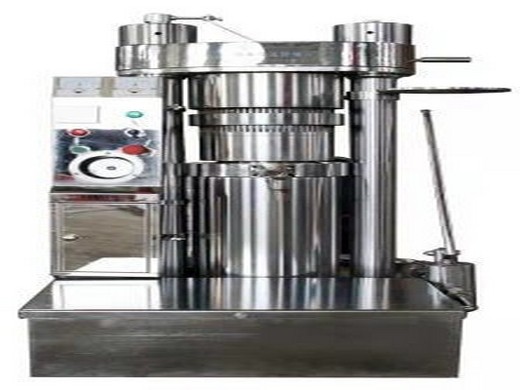

Using screw press machine one is natural and healthy, but the oil yield is much lower than solvent extraction machine. You can choose one according to the capacity and your requirements of the soybean oil processing plant, or you can use the two together. Common Soybean Oil Extraction Process for Large Scale Soybean Oil Mill Plant:

Professional Process of Soybean Oil Production

Extraction Section of Soybean Oil Production: First the soybeans are cut in flakes which are put in a percolation extractors and immerged with a solvent, normally hexane. Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators.

An animal study compared the impact of a diet high in soybean oil to high fructose and coconut oil diets. The mice fed large amounts of soybean oil had significantly more weight gain, diabetes, and insulin resistance. Additionally, the soybean oil diet upregulated cancer, inflammation and obesity-related genes (2).

Fast Separation of Triacylglycerols in Oils using

Figure 1 shows UV, ELSD, and MS chromatograms for the separation of TAGs in soybean oil. All of the effluent first passes through the PDA flow cell and then to the back pressure regulator and the ELSD using the PEEK ELSD splitter kit (205001048). Each gradient separation was performed at 25 °C with an ACQUITY UPC 2 HSS C 18

Solvent extraction of soybean . Basic principles and elements of solvent extraction; Oil extraction is to extract the oil from the embryo by wetting and infiltration, molecular diffusion and convective diffusion with solvent which can dissolve the oil.

Separation of soybean oil/n-hexane and soybean oil/n

In the separation of the oil/n-butane mixtures, higher oil rejections were obtained when compared to the system oil/n-hexane. The results presented in this work indicate the potential applicability of membrane technology in vegetable oil processing and biodiesel industries in the solvent recovery step.

GET PRICE

Separation and purification of squalene from soybean oil

In the refining of soybean oil, most bioactive compounds such as squalene, fatty acid steryl esters (FASEs), tocopherols and free phytosterols are concentrated in intermediate byproducts and waste streams , . SODD is obtained as a byproduct of the deodorization step during the refining of soybean oil.

GET PRICE

Investigation of phospholipid separation from soybean oil

Crude soybean oil contains impurities that can be classified into two categories: oil insoluble and oil soluble. The oil insoluble impurities consist of seed fragments and meal fines, free water and long chain hydrocarbons or waxes. Most of these materials can be removed by filtration. The oil-soluble materials include free fatty acids, phosphatides,

GET PRICE

Analysis of Triglycerides of Soybean Oil by High

triglycerides of soybean oil. The triglycerides were clearly separated into six peaks by HPLC on a column packed with ,ƒÊ-Bondapack C18 using methanol-chloroform mixture as a solvent. From the fatty acid compositions of the triglycerides of these six peaks, it was found that the separation of triglycerides

GET PRICE

Separation of Soybean Oil/n-hexane Miscellas Using

Separation of refined soybean oil/n-hexane miscellas was studied using different commercial ultra-and nanofiltration membranes, with cutoffs in the range of 1 to 5 kDa and salt rejection higher ...

GET PRICE

Soybean oil extraction and separation using switchable or

Soybean oil extraction and separation using switchable or expanded solvents. Lam Phan a, Heather Brown b, James White b, Allan Hodgson c and Philip G. Jessop * a a Department of Chemistry, Queen's University, Kingston, Ontario, Canada.

GET PRICE

Solvent extraction process of soybean - Edible Oil

Solvent extraction of soybean . Basic principles and elements of solvent extraction; Oil extraction is to extract the oil from the embryo by wetting and infiltration, molecular diffusion and convective diffusion with solvent which can dissolve the oil.

GET PRICE

SOLVENT RECOVERY FROM SOYBEAN OIL/N-HEXANE MIXTURES USING

investigate the separation of refined soybean oil/n-hexane mixtures using a hollow fiber ultrafiltration membrane, testing the effect of pre-treatment on the membrane permeability to n-hexane. MATERIALS AND METHODS Membrane and Equipment Permeation assays were performed using a hollow fiber ultrafiltration (UF) membrane module,

GET PRICE

Separation of soybean oil from liquefied n‐butane

This work investigates the separation of soybean oil/compressed n‐butane and soybean oil/liquefied petroleum gas (LPG) mixtures, using ultra‐ and nanofiltration membranes. For this purpose, soybean oil/n‐butane and soybean oil/LPG in the mass ratio of 1:3 were continuously fed into a flat sheet module without the recycle.

GET PRICE

Separation of soybean oil from liquefied n‐butane

This work investigates the separation of soybean oil/compressed n‐butane and soybean oil/liquefied petroleum gas (LPG) mixtures, using ultra‐ and nanofiltration membranes. For this purpose, soybean oil/n‐butane and soybean oil/LPG in the mass ratio of 1:3 were continuously fed into a flat sheet module without the recycle.

GET PRICE

SOLVENT EXTRACTION OF OIL FROM SOYBEANS - Industrial

Abstract: Soybeans contain oil bodies that are coated by a layer of oleosin proteins. In nature, this protein coating protects the oil bodies from environmental stresses and may be utilized by food manufacturers for the same purpose.

GET PRICE

Transesterification of soybean oil by using the

The acid value and saponification value of this type of soybean oil were previously determined as 0.7 mgKOH·g −1 and 194.95 mgKOH·g −1, hence the average molecular weight of this soybean oil was calculated to be 866.41 g·mol −1. The soybean oil was heated under 120 °C for 2 h before use, so as to purge the trace amount of water in it.

GET PRICE

Separation of soybean oil/n-hexane and soybean oil/n

Separation of refined soybean oil/n-butane mixtures was studied in this work using different commercial ultra- and nanofiltration membranes, with cut-offs ranging from 1 to 5kDa.

GET PRICE

Separation of soybean oil from liquefied n‐butane

This work investigates the separation of soybean oil/compressed n‐butane and soybean oil/liquefied petroleum gas (LPG) mixtures, using ultra‐ and nanofiltration membranes. For this purpose, soybean oil/n‐butane and soybean oil/LPG in the mass ratio of 1:3 were continuously fed into a flat sheet module without the recycle.

GET PRICE

Protein and oil recoveries from enzyme-assisted aqueous

how oil is contained within a soybean and to state the physical nature of the barriers to oil release. Then, the effects of a range of physical treatments on the microstructure of soybean will be discussed. Soybean Cotyledon Microstructure Typical soybean composition is 20% oil, 40% protein, 35% carbohydrate, and 5% ash on a dry basis.[1]

GET PRICE

Analysis of Triglycerides of Soybean Oil by High

triglycerides of soybean oil. The triglycerides were clearly separated into six peaks by HPLC on a column packed with ,ƒÊ-Bondapack C18 using methanol-chloroform mixture as a solvent. From the fatty acid compositions of the triglycerides of these six peaks, it was found that the separation of triglycerides

GET PRICE

Isolation of soybean protein P34 from oil bodies using

Soy proteins are extracted from soybean oil bodies using sodium carbonate buffer, similar to the procedure described by Herman . This procedure is shown schematically in Fig. 1. Subsequently, the solution is diafiltrated and P34 is purified using hydrophobic interaction chromatography (HIC).

GET PRICE

Epoxidation of soybean oil to obtain ESBO

Epoxidation of soybean oil to obtain ESBO. Oxidative cleavage of the double bond of oleic acid to obtain nonanoic and azelaic acids Double bonds hydrogenation with particular reference to partial hydrogenation of vegetable oils. Polyethoxylation and polypropoxylation. Synthesis of hydrogen peroxide via antraquinone

GET PRICE

Rice bran oil extraction process | rice bran oil machine

4, henan huatai rice bran oil extraction technology use multiple heat exchange system , make full use of the heat source system, effectively reduce the steam consumption, at the same time the rice bran oil extraction process can be adjusted, flexible operation, automation, environmental health, etc.

GET PRICE

Improving the yield of soybean oil extraction process

The increasing use of soybeans, as the century’s strategic plant , makes the economy necessary in energy consumption for separating oil from this valuable seed. Soybeans are a rich source of proteins, lecithin and isoflavones. , and soxhlet extraction and extraction by compound extractors.

GET PRICE