3. PALM OIL PROCESSING - Home | Food and Agriculture

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

Palm oil mill process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery. 1. Palm oil mill process of fruits receiving: Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground ...

PowerPoint Presentation

VITAMIN E IN PALM OIL Crude oil and red palm oil- highest content of tocotrienols. 70% retained in refined oils. Mostly in form of y tocotrienols. Antioxidant activity -y > > ct tocotrienol improve oxidative stability by factor 6.3.

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

What are the steps in palm oil production?_Palm Oil

For further processing of palm oil,the palm oil refining process and palm oil fractionation process is necessary.The palm oil refining process can get rid of the harmful impurities and needless substance in the crude edible oil, getting standard edible oil by utilizing the physical methods and chemical processes.

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Extraction Machine. Capacity 5-100T/H. Oilseed Palm Fruit/ Kernel. Application palm fruit (FFB) and palm bunches. Description Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

Palm Oil Mill Machine_palm oil processing machine,edible

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted. A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 - 150 MT FFB/hr.

Palm oil milling process - SlideShare

A palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons F… Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

3. PALM OIL PROCESSING Food and Agriculture

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

GET PRICE

Crude Palm Oil Milling Process MVO

crude palm oil milling process plantation ffb in ffb cage sterilising ffb threshing stripped bunches fertiliser effluent treatment steam injection digesting pressed pressing cake shells nuts cpo fibres co-generation depericafing clear oil oil purification drying crude palm oil storage refinery palm kernel crushing plant palm kernel out kernel

GET PRICE

Palm Oil Mill Machine_palm oil processing machine,edible

Palm oil mill plant adopts the most scientific palm oil processing equipment configuration, using mechanical oil pressing technology, make successfully extraction of palm oil from palm fruit. Palm oil milling process plant covers three major plants of crude palm oil pressing plant, water treatment plant and power supply plant.

GET PRICE

Crude Palm Oil Production Process Palm Oil Mill Machine

Crude Palm Oil Mill Process Introduction:. 1.Weighing.Palm fruit into the factory after truck weighing,ease of production costing and after the settlement. 2.Loading ramp.FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank.

GET PRICE

Premium Design of Palm Oil Milling Process with Cost

The palm fruit receive the palm oil mill as fruit bunch which is embedded with many small individual fruits. In the threshing station of palm oil mill, the individual fruits will be detached from the bunch by use of FFBs thresher/stripper.Rotating drum and fixed drum are the two main threshing machine applied in palm oil milling process.

GET PRICE

Palm and Palm Kernel Oil Production and Processing

The overall palm oil milling efficiency in terms of oil recovery is typically about 90–93%, depending on plant machinery and process control. The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18–23% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%.

GET PRICE

WACAPOL Palm Oil Mill 2024 wacapol

With 30 years of palm oil processing experience in Africa, this mill has been designed and built in the UK to operate in remote environments at lower throughputs with the minimum of skills and

GET PRICE

Palm Oil Mill Process Steam Boiler

PALM OIL MILLING. PROCESS FLOWCHART OF PALM OIL MILL PROCESSING 1.Bunch Reception. 2.Sterilizatio n Empty EB fiber Bunch 4.EB Compost for 3.Threshing Pressing plantations Nut 10.Kernal Station 8.Sludge 5.Digestion Oil EB Oil Press Recover 11.Boiler/ Fiber 6.Pressing y Turbine

GET PRICE

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil

Palm Fruit ( Kernel) Oil Processing Machine/Palm Oil Extraction Machine. Capacity 5-100T/H. Oilseed Palm Fruit/ Kernel. Application palm fruit (FFB) and palm bunches. Description Henan huatai palm oil processing main processes: weighing, unloading fruit, sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

GET PRICE

Alfa Laval Palm oil processing

50 years of innovation in palm oil. From milling, waste management, refinery to service Alfa Laval has the right process solution for you. Dr. Bent Sarup, VP Edible Oil Systems, also gave us a glimpse of what Alfa Laval is currently working on ZeroGE™ a revolutionary technology aimed at creating a more sustainable future for palm oil.

GET PRICE

Palm Oil Mill Mecpro

The concept of Mecpro’s mill is using the latest in palm oil milling technology to enhance efficiency with low operating cost. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB.

GET PRICE

10 Ton Oil Palm Processing Milling Machines In Nigeria

10 Ton Oil Palm Processing Milling Machines In Nigeria And Crude Palm Oil Refining Production Line For Sale,Find Complete Details about 10 Ton Oil Palm Processing Milling Machines In Nigeria And Crude Palm Oil Refining Production Line For Sale,Palm Kernel Oil Mill Plant,Small Palm Oil Mill,Palm Oil Processing Mill Plant from Oil Pressers Supplier or Manufacturer-Henan Qi'e Grain And Oil

GET PRICE

Fish Oil Refining Process, 3ton/day Refinery Plant

Whenever you want to know more about fish oil production methods, fish oil refining process, or related equipments, welcome to send us an inquiry!We can help you on fish oil extraction and refinery step by step for FREE! Here is another Fish Oil Refining Project established in Nigeria for Reference: 5TPD Sardine Fish Oil Refinery. It is designed and built for fish oil deep processing to

GET PRICE

STUDIES ON FLOW PERFORMANCE OF CRUDE PALM OIL IN

D Crude palm oil milling process in Malaysia 39 E Pigging process 40 . 1 CHAPTER 1 INTRODUCTION 1.1 Background of Study The first oil palm plantation in Malaysia started in 1917 when oil palm trees first introduced to Malaysia as an ornamental tree. Sabah is the largest palm oil producer in Malaysia, It has about 1.2 million hectares of some of the highest-yielding oil palm plantations (21.4

GET PRICE

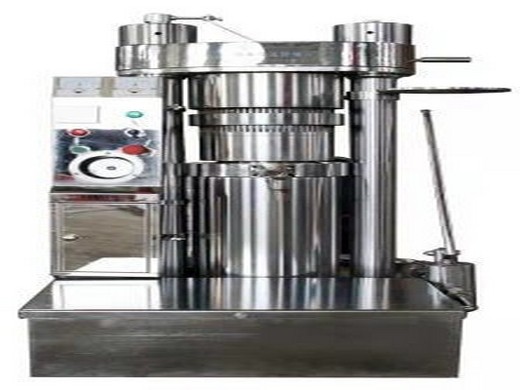

Oil mill

An oil mill is a grinding mill designed to crush or bruise oil-bearing seeds, such as linseed or peanuts, or other oil-rich vegetable material, such as olives or the fruit of the oil palm, which can then be pressed to extract vegetable oils, which may used as foods or for cooking, as

GET PRICE

FRESH FRUIT BUNCH QUALITY AND OIL LOSSES IN MILLING

Oil palm (Elaeis guineensis Jacq.) industry is one of the fastest growing sectors in Malaysia, where currently Malaysia is the second largest producer of palm oil in the world. Through the milling processes, Crude Palm Oil (CPO) was extracted from

GET PRICE

Palm oil

Palm oil is used to produce both methyl ester and hydrodeoxygenated biodiesel. Palm oil methyl ester is created through a process called transesterification. Palm oil biodiesel is often blended with other fuels to create palm oil biodiesel blends. Palm oil biodiesel

GET PRICE

Palm oil

Palm oil is used to produce both methyl ester and hydrodeoxygenated biodiesel. Palm oil methyl ester is created through a process called transesterification. Palm oil biodiesel is often blended with other fuels to create palm oil biodiesel blends. Palm oil biodiesel

GET PRICE

Developing a Palm Oil Sector: The Experiences of Malaysia

tors that affect the process of upgrading and innovation, through a comparative assessment of the experiences of Malaysia and Ghana in the palm oil sector. The purpose is not to carry out a direct comparison of the trajectories of the sectors in the two countries, which would serve only to em-

GET PRICE

High Quality 100tpd Crude Palm Oil Milling Process

High Quality 100tpd Crude Palm Oil Milling Process Machines In Nigeria,Find Complete Details about High Quality 100tpd Crude Palm Oil Milling Process Machines In Nigeria,Crude Palm Oil Process,Crude Palm Oil Milling Process,100tpd Palm Oil Milling Machines In Nigeria from Oil Pressers Supplier or Manufacturer-.

GET PRICE

Palm Oil Milling Line

Highly Efficient Palm Oil Milling Process for Palm Oil Mill. A palm oil milling process plant produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FFB/h.

GET PRICE

Highly Efficient Palm Oil Milling Process for Palm Oil Mill

A palm oil milling process plant produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FFB/h. A typical mill has many operation units as shown in the picture below.

GET PRICE

SEPARATION TEHCNIQUE OF CRUDE PALM OIL AT

SEPARATION TEHCNIQUE OF CRUDE PALM OIL AT CLARIFICATION AREA VIA OPTIMUM PARAMETERS TITLE OF PAGE NURULHUDA BINTI KASIM A thesis submitted in fulfillment of the requirement for the award of the degree of Bachelor of Chemical Engineering Faculty of Chemical and Natural Resources Engineering Universiti Malaysia Pahang APRIL 2009 . ii DECLARATION I declare

GET PRICE

Flowsheet Synthesis and Optimisation of Palm Oil Milling

Abstract. Crude palm oil (CPO) is produced in palm oil mills (POMs) using fresh fruit bunches (FFBs), harvested from oil palm plantations. FFB passes through multiple unit operations in the milling process, each consists of different technologies.

GET PRICE

Zero-waste palm oil industry on the horizon with new

Malaysia is the second-largest crude palm oil producer in the world and fulfils nearly half of all demand for the oil, which is now used in a huge variety of foodstuffs and household products

GET PRICE