Corn oil - Producing countries (Tons) - 2024

3 - Japan - Corn oil - Production (Tons) was 110,000 Tons in 1994 4 - Brazil - Corn oil - Production (Tons) was 93,797 Tons in 2013 5 - South Africa - Corn oil - Production (Tons) was 80,700 Tons in 2013 The 5 lowest records for sovereign countries (1 per country) since 1961 : 1 - Ukraine - Corn oil - Production (Tons) was 0 Tons in 1992

Production. Almost all corn germ oil is expeller-pressed, then solvent-extracted using hexane or 2-methylpentane (isohexane). The solvent is evaporated from the corn germ oil, recovered, and re-used. After extraction, the corn germ oil is then refined by degumming and/or alkali treatment, both of which remove phosphatides.Alkali treatment also neutralizes free fatty acids and removes color (bleaching).

Professional Corn Oil Production Process - Supplied by Oil

Corn Oil Production Process - Solvent Extraction The corn germ oil in the hexane solution is heated to vaporize the volatile solvent, which is captured as a condensate and used again. Then the heat expelled and hexane extracted oils are combined as crude corn germ oil; the remaining cake is processed for livestock feed.

Kazakhstan : 22 records since 1992 , the average of these recordings : 305 Tons The highest data : 2011 is the highest year for the indicator : Corn oil - Production (Tons). The result is: 1,607 Tons. The lowest data : 1993 is the lowest year for the indicator : Corn oil - Production (Tons). The result is: 0 Tons.

Corn Oil Extraction Plant, Corn Oil Processing Plant

Corn oil extraction plant is suitable for large-scale corn germ oil production. Adopt prepressing extraction technology, this corn germ oil plant has a large capacity and short extraction time. The crude oil obtained has few impurities, shallow color, and high quality.

The lowest data : 1993 is the lowest year for the indicator : Corn oil - Production (Tons). The result is: 0 Tons. Below you will find the last recordings for the indicator : Corn oil - Production (Tons). The analysed country is : Kazakhstan. Kazakhstan : Table - Corn oil - Production (Tons)

Corn Oil Extraction Plant, Corn Oil Processing Plant

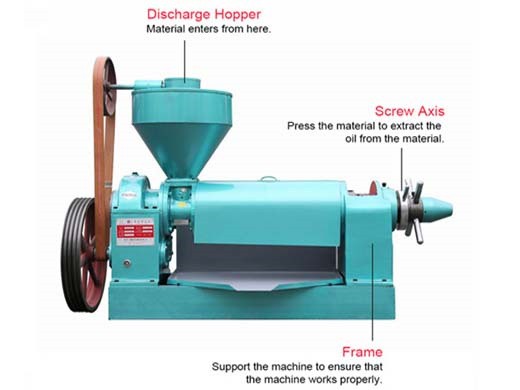

Introduction to Corn Oil Extraction Plant. Corn oil extraction plant extracts corn germ from corn germ and produces corn germ oil by solvent extraction method.The corn germ oil production line includes corn germ extraction process, corn germ pretreatment and prepressing process, corn germ cake solvent extraction process and crude corn germ oil refining process.

Corn Oil We are operating corn germ oil recovery systems at all of our plants. The corn germ oil systems we installed are designed to recover non-edible corn germ oil from the thin stillage evaporation process immediately prior to production of distillers grains.

Professional Corn Oil Production Process - Supplied by Oil

KMECis always committed to offer professional corn germ oil production process and quality corn germ oil production machines. we are your trustable manufacturer and supplier of oil production in China.. Corn oil is a commonly used oil that is used by many around the world for their cooking needs. Corn oil production process is a complicated process.

Corn oil production process. There are 2 ways to make oil from corn germ: one is pressing method, which is suitable for small to medium size oil mill plant; the second is solvent extraction method, which is suitable for large scale oil factory; the third is aqueous enzymatic method, which is a new method developed in recent years.

Corn Oil | Green Plains Inc.

Corn Oil We are operating corn germ oil recovery systems at all of our plants. The corn germ oil systems we installed are designed to recover non-edible corn germ oil from the thin stillage evaporation process immediately prior to production of distillers grains.

GET PRICE

Corn Processing - Crown Iron Works

The corn germ oil can be further refined from a crude product to an edible product. Oil Refining and Processing. Extracted and desolventized corn germ oil must be further processed to make an edible product. Edible oils are refined to improve the flavor, odor, color and stability using processes that degum, neutralize, bleach and deodorize the oil. These

GET PRICE

The Composition of Crude Corn Oil Recovered after

cal composition of corn germ oil obtained after fermentation of corn germ to make fuel ethanol via centrifugation and compare its composition to that of corn germ oil (commercial corn germ oil) and experimental corn germ oils. The levels of free fatty acids in the post fermentation corn germ oil were high (11–16%), as previously reported. The levels of free

GET PRICE

Corn Oil Extraction - GreenShift - Clean Technologies

Today, GreenShift’s portfolio of corn germ oil extraction processes is widely considered to be the quickest path for margin improvement for corn germ ethanol producers. GreenShift’s patented process is installed at over 80% of the corn germ-based, dry mill ethanol facilities in the United States, producing roughly 1.8 billion pounds and over $700 million

GET PRICE

Specialist of Cooking Oil Production and Its Process

Cooking oil is purified fat of plant origin, which is usually liquid at room temperature, cooking oil production, however,is really not a simple process as you can image. some of the many different kinds of edible vegetable oils include: olive oil, palm oil, soybean oil, canola oil, pumpkin seed oil, corn germ oil, sunflower oil, safflower oil, peanut oil, grape seed oil, sesame oil, argan oil and

GET PRICE

Corn Oil | Greenfield

Greenfield’s Chatham, Varennes, and Johnstown plants are all operating corn germ oil recovery systems which extract corn germ oil from the thin stillage evaporation process immediately prior to the production of distiller’s grains. Valued for its high energy content, distillers corn germ oil is commonly used as a feedstock for biodiesel production or as an valued ingredient in …

GET PRICE

Corn germ oil extraction cold press Pakistan

Corn germ oil extraction cold press Pakistan Fantastic train wheel production process and other amazing making process. Incredible technology. Modern Process of Plywood Processing Line !

GET PRICE

Corn oil production process - Edible Oil Expeller Machinery

The process of corn germ oil extraction includes the separation of embryos and the extraction of embryos. 1. Separation of embryos. The separation of corn germ mainly consists of dry desquamation and wet grinding.Dry desquamation and embryo preparation means that the raw material is directly desquamated and embryo preparation without water treatment.

GET PRICE

Corn Oil Extraction - GreenShift - Clean Technologies

Today, GreenShift’s portfolio of corn germ oil extraction processes is widely considered to be the quickest path for margin improvement for corn germ ethanol producers. GreenShift’s patented process is installed at over 80% of the corn germ-based, dry mill ethanol facilities in the United States, producing roughly 1.8 billion pounds and over $700 million

GET PRICE

Health Benefits of Corn Oil, Process of Making Corn Oil

Benefits of corn germ not only as a source of carbohydrates, but also as a raw material for various products such as fodder, raw materials corn germstarch, and corn germ oil. On this occasion, we will see what are the health benefits of corn germ oil and how the process of making corn germ oil. How the Process of Making Corn Oil

GET PRICE

The Corn Refining Process

oil (extracted from the germ), and two percent is fiber (from the hull). It is the goal of the corn germ refining process to separate each component and then further refine it into specific products. Corn arrives at the refining facility by truck, barge or railcar. Refinery staff inspect arriving corn germ

GET PRICE

Corn Oil Extraction - North Dakota

the technology from all providers involves using a centrifuge to separate corn germ oil from thin stillage. Project management is continuing to investigate technology providers to ensure optimal compatibility with our facility. The process for corn germ oil extraction is very similar with all technology suppliers.

GET PRICE

Corn Processing - Crown Iron Works

The corn germ oil can be further refined from a crude product to an edible product. Oil Refining and Processing. Extracted and desolventized corn germ oil must be further processed to make an edible product. Edible oils are refined to improve the flavor, odor, color and stability using processes that degum, neutralize, bleach and deodorize the oil. These

GET PRICE

Corn-Based Ethanol Plants Diversify to Survive

Quad County added KFT to produce high protein feed, additional distiller's corn germ oil, and cellulosic ethanol from the corn germ kernel fiber contained in the corn germ it purchases, Johnson says. The plant is currently licensing the technology to the ethanol industry as a way for each plant to get more value out of each kernel of corn germ they process.

GET PRICE

processes

associated with corn germ ethanol production [14]. Nonfermentable coproducts, produced from a dry grind process, are commonly in the form of distillers’ wet grains (DWG) or distillers’ dried grains with solubles (DDGS), while coproducts in a wet milling process are in the form of corn germ gluten meal or corn germ gluten feed [15].

GET PRICE

Production of biodiesel from corn germ oil and ethanol

Production of biodiesel from corn germ oil and ethanol by homogeneous alkali catalyzed April 2011 . Production of biodiesel from corn germ oil and ethanol by homogeneous alkali catalyzed transesterification MSc. thesis Atahualpa Moura Mendes Supervisor Rolando Zanzi Vigouroux NO x and the high costs related to feedstock and the production process.

GET PRICE