Zero-waste palm oil industry on the horizon with new

Engineers at the University of Nottingham Malaysia have developed new technology to help the global palm oil processing industry reduce CO2 emissions and create renewable energy from its waste.

Palm oil automatic control dewaxing and degreasing process work under slowly stirring and cooling the oil to certain temperature in fixed time (technical security), and make waxy formed bigger crystallization, then separation exhalation, after filtering, it separates the fluid oil and solid fat.

Dewaxing and Degreasing technology

Dewaxing and Degreasing technology. Rice bran oil automatic control dewaxing and degrease process work under slowly stirring and cool the oil to certain temperature at 4-6℃, and make waxy formed bigger crystallization, then separation exhalation, after filtering, it separates the fluid oil and solid fat.

Advantages of the new dewaxing technology High oil quality The salad oil produced by this process not only meets the national standard 5.5-hour winterization test standard, but also meets the 11-hour winterization test standard of European and American dewaxed oil.

Edible Oil Refining Processes - Degumming / Neutralization

THE DEWAXING PROCESS Definition & Overview Dewaxing: Separation of waxes, esters of long chain fatty acids and long chain primary alcohols present in mainly sunflower and maize oil. Winterisation: Separation of saturated triacylglycerols from e.g. cottonseed oil and partly hydrogenated oils. Some oils are dewaxed before packing so as to remove waxes, which are dissolved in the oil.

Wet Dewaxing. SRS’ dewaxing unit utlizes the same process as the degumming unit. See SRS’ degumming process technology This system is used to remove the wax that is commonly found in corn oil. During ethanol production, ten percent of the residual byproduct is corn oil. The problem with this corn oil is it is very high in FFA (Free Fatty ...

EDIBLE OILS AND FATS REFINING

In both systems (cold refining and wet dewaxing) the oil is cooled at 7 ÷ 8°C and then sent to crystallizers where it remains from 8 to 12 hours. In order to reduce the oil viscosity without dissolving the formed crystals, a light increase of the oil temperature up to 15°C is carried out before sending it to the dewaxing separator.

Palm Oil Refining Process Palm Oil Refining Process Our small scale palm oil refining plant are great choice for small capacity palm oil refinery plant.The small scale palm oil refining plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the crude palm oi,palm kernel oil refining process ,etc.

Zero-waste palm oil industry on the horizon with new

Engineers at the University of Nottingham Malaysia have developed new technology to help the global palm oil processing industry reduce CO2 emissions and create renewable energy from its waste.

Palm oil automatic control dewaxing and degreasing process work under slowly stirring and cooling the oil to certain temperature in fixed time (technical security), and make waxy formed bigger crystallization, then separation exhalation, after filtering, it separates the fluid oil and solid fat.

How new technology is helping the palm oil industry

This post was originally published on March 26, 2024 and updated on December 30, 2024. Private industry and the Malaysian Palm Oil Board (MPOB), a Malaysian government research institute, are joining forces to increase oil palm production by using technology to identify the highest yielding trees.

GET PRICE

Membrane Technology in Degumming, Dewaxing, Deacidifying

A membrane process offers several advantages over the conventional method of oil refining. Conceptually, membranes could be used in almost all stages of processing. In the present review, various attempts made by the researchers towards degumming, dewaxing, deacidifying, and decolorizing edible oils using membrane technology with and without using solvents have been discussed.

GET PRICE

New technology to improve sustainability of MY palm oil

The new technology will be supplied by Japanese equipment manufacturer – Kubota – and is based on the companies ‘Anaerobic and Aerobic Membrane Bioreactor System’. The system works to extract biogas from Palm Oil Mill Effluent (POME), a by-product created during palm oil milling.

GET PRICE

The Technology of Palm Oil Refining Processing

Nowdays,consupmtion of palm is more and more,the business of the palce with palm oil production is hot,the hot-selling of palm oil make them life more easy.There,many farms plant palm tree,it is a economic vegetable fro them,you plant them ,the trees will provide you palm fruit for at least 25 years.more and more people do not sell palm fruit to others,they produce palm oil with the help of ...

GET PRICE

New technology to improve sustainability of MY palm oil

The new technology will be supplied by Japanese equipment manufacturer – Kubota – and is based on the companies ‘Anaerobic and Aerobic Membrane Bioreactor System’. The system works to extract biogas from Palm Oil Mill Effluent (POME), a by-product created during palm oil milling.

GET PRICE

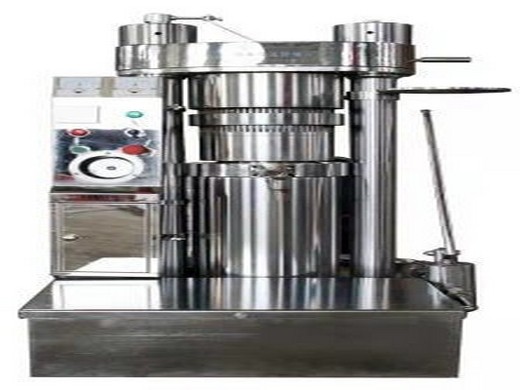

20-3000T/D dewaxing project - ZHENGZHOU PALM OIL MACHINERY

Palm oil fractionation is a kind of new oil processing technology. With this technology, you can get palm oil with different melting points, like 33*C, 24*C,18*C,14*C,12*C,10*C,8*C,etc. you can get high purity of solid fat and high economic benefits.

GET PRICE

Reducing the environmental impact of palm oil production

Reducing the environmental impact of palm oil production. “Once it is commercialised, our technology will enable palm oil processing facilities to turn oil palm fronds, trunks and empty fruit bunches into dried long fibre for matting, pallets, briquettes and biofuels,” said project lead Denny Ng from the university’s faculty of engineering.

GET PRICE

Palm oil fractionation - Oil

Palm oil franctionation is a new item of oil processing technology, palm oil franctionation process can get different melting point of palm oil products with 8 ℃, 10 ℃, 14 ℃, 18 ℃, 24 ℃, 33 ℃, 44℃, 55℃, etc. while also can used to processing cottonseed oil, and fish oil and lard, all kinds animal oil, greatly improve the value-added of products, increase the economic of enterprise.

GET PRICE

3. PALM OIL PROCESSING

PALM OIL PROCESSING UNIT OPERATIONS. Harvesting technique and handling effects. In the early stages of fruit formation, the oil content of the fruit is very low. As the fruit approaches maturity the formation of oil increases rapidly to about 50 percent of mesocarp weigh.

GET PRICE

EDIBLE OILS AND FATS REFINING

In both systems (cold refining and wet dewaxing) the oil is cooled at 7 ÷ 8°C and then sent to crystallizers where it remains from 8 to 12 hours. In order to reduce the oil viscosity without dissolving the formed crystals, a light increase of the oil temperature up to 15°C is carried out before sending it to the dewaxing separator.

GET PRICE

Reducing the environmental impact of palm oil production

NEW technology has been developed that will convert palm oil waste into building materials and biofuels. Palm oil is a vegetable oil that is used in a wide range of products including food, cosmetics, and household products. While the long-term sustainability of palm oil production has attracted ...

GET PRICE

Palm Oil’s Changing Fortunes Signal Brighter Outlook

What’s more, relentless pressure from NGOs to stop oil palm planting, as well as the slowdown in new planting due to low prices earlier will inevitably keep production growth low in the next few ...

GET PRICE

3. PALM OIL PROCESSING

PALM OIL PROCESSING UNIT OPERATIONS. Harvesting technique and handling effects. In the early stages of fruit formation, the oil content of the fruit is very low. As the fruit approaches maturity the formation of oil increases rapidly to about 50 percent of mesocarp weigh.

GET PRICE

Dewaxing

Dewaxing. Dewaxing of waxes is the separation process at low temperature, as the temperature decreases, the polarity of the ester bond in enhanced oil wax molecules at less than 30 ℃ (about 0 ℃) i.e. formation of crystallized, forming more stable colloidal system. In this low for some time after the wax crystals agglomerate to form larger ...

GET PRICE

benefits of begetable oil production_Manufacturer

The culinary oils listed in a recent natural foods catalog include-in addition to olive oil-sesame, safflower, sunflower, grape seed, canola, apricot kernel, coconut, haxzelnut, peanut, pumpkin, and walnut oils. Advertisements for these culinary oil tout their health benefits and unique flavors.

GET PRICE

coconut, palm Oil Press Processing turnkey project

Palm oil fractionation technology developed by Xinxiang Jinxin Company is with advanced technology,full computer control system and low cost of investment. It is also with high liquid oil yield,high purity solid fat, high economic benefit, and other advantages etc.

GET PRICE